servo drives add precision and synchronisation between the fill volume and diving nozzle mechanism, enabling fill rates to be maximised.

Servo drives also have the advantage of being able to store settings in a memory, allowing you to recall settings that will be 100% repeatable and enabling product changeovers to be faster and cleaner than ever before.

• Ergonomically designed for easy access for rapid changeovers and cleaning.

• On screen speed and fill adjustment.

• Fully adjustable dive unit for neck entry or bottom-up filling.

• Suitable for handling a wide range of container shapes and sizes.

• Does not require highly trained operators.

• Simple to use and maintain.

• Fills liquids, semi-liquids and liquids with particulates.

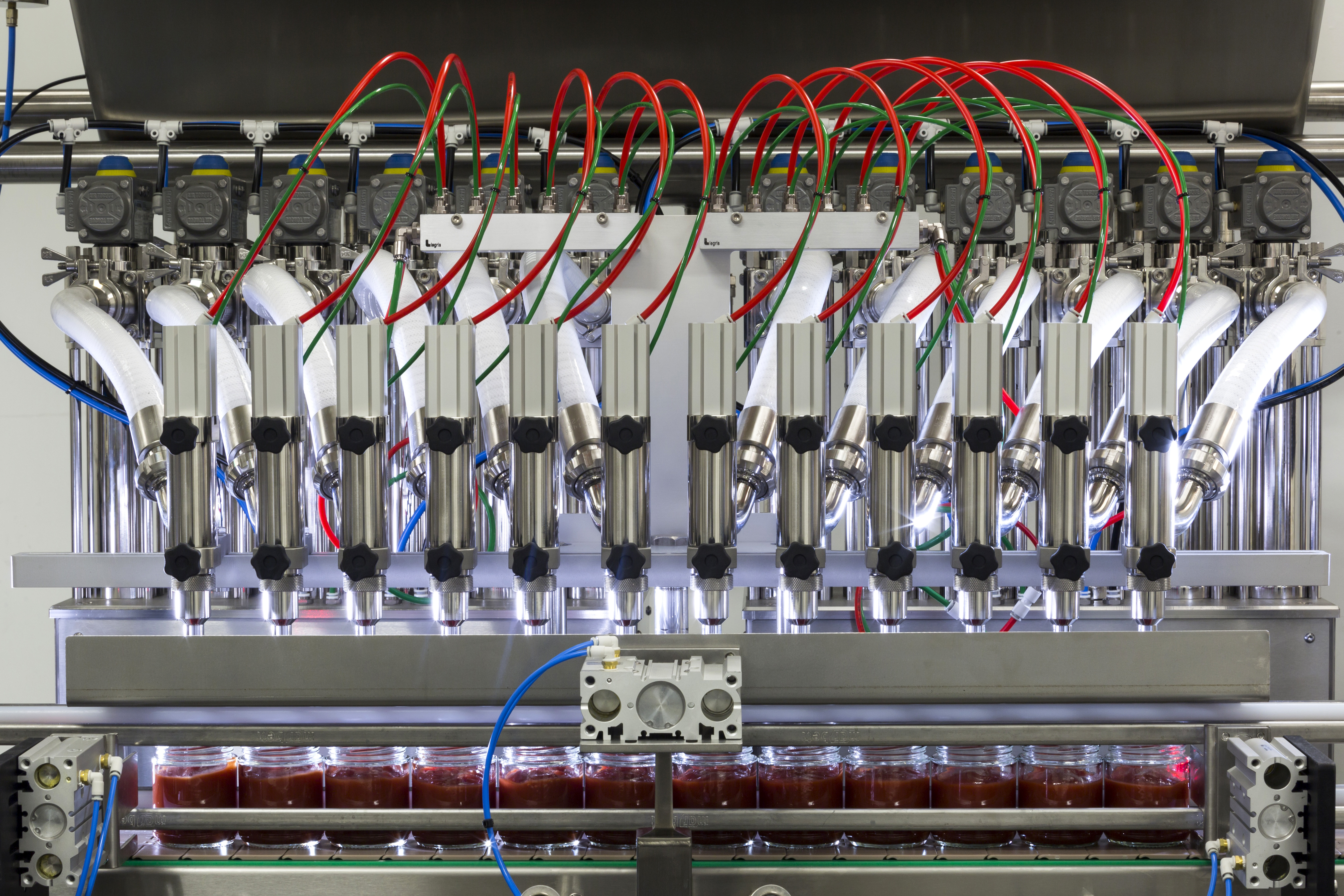

• Available format: 2,4, 6, 8 or 12 heads.

• Dispensing volumes: 5ml – 1,300ml.

• Filling speeds: Up to 150 BPM.

• Fill accuracy: Up to+/- 0.5%.

• Food and pharmaceutical quality stainless steel contact parts.